A bird's eye view of Jidong Cements Bishan. (Photo: Jidong Cements Bishan Co., Ltd.)

It is hard to imagine a factory with a farm on its rooftop, but this is happening at the plant of Mexin Messon Doors Industry, a manufacturer of windows and doors based in Southwest China's Chongqing.

The rooftop farm covers over 20,000 square meters. Employees of the factory can grow vegetables, fruits, cereals and flowers in their off time. When the rain stops, there is a mixed fragrance of plants. The manufacturer was recognized by authority as a green factory in 2019.

A green factory, according to an evaluation guideline implemented by China in 2018, features intensive land use, adopts hazard-free raw materials, practices clean production, recycles waste and employs low-carbon energy.

As a major manufacturing hub, Chongqing has vigorously promoted green transition among its enterprises. According to a municipal plan, Chongqing will be home to over 30 green industrial parks and 300 green factories by 2025, and it will strive to lower the energy consumption per unit of value added of enterprises above a designated size by 14.5 percent from 2020.

Manufacturers in Chongqing have been adding gardens to their factories in recent years. In the general assembly center of China State Shipbuilding Corporation Haizhuang Windpower in Chongqing's Liangjiang New Area, trees and flowers can be seen everywhere, and there are even ponds. The vegetation cover helps the center maintain a sound ecology, keeps it at an appropriate temperature, and reduces noise.

Industrial enterprises in the municipality have spared no effort to cut energy consumption and promote green development. They have managed to make full use of sunlight to reduce electricity consumption, greened their factories to consume less energy, and adopted shock absorption and noise insulation techniques to make production quieter.

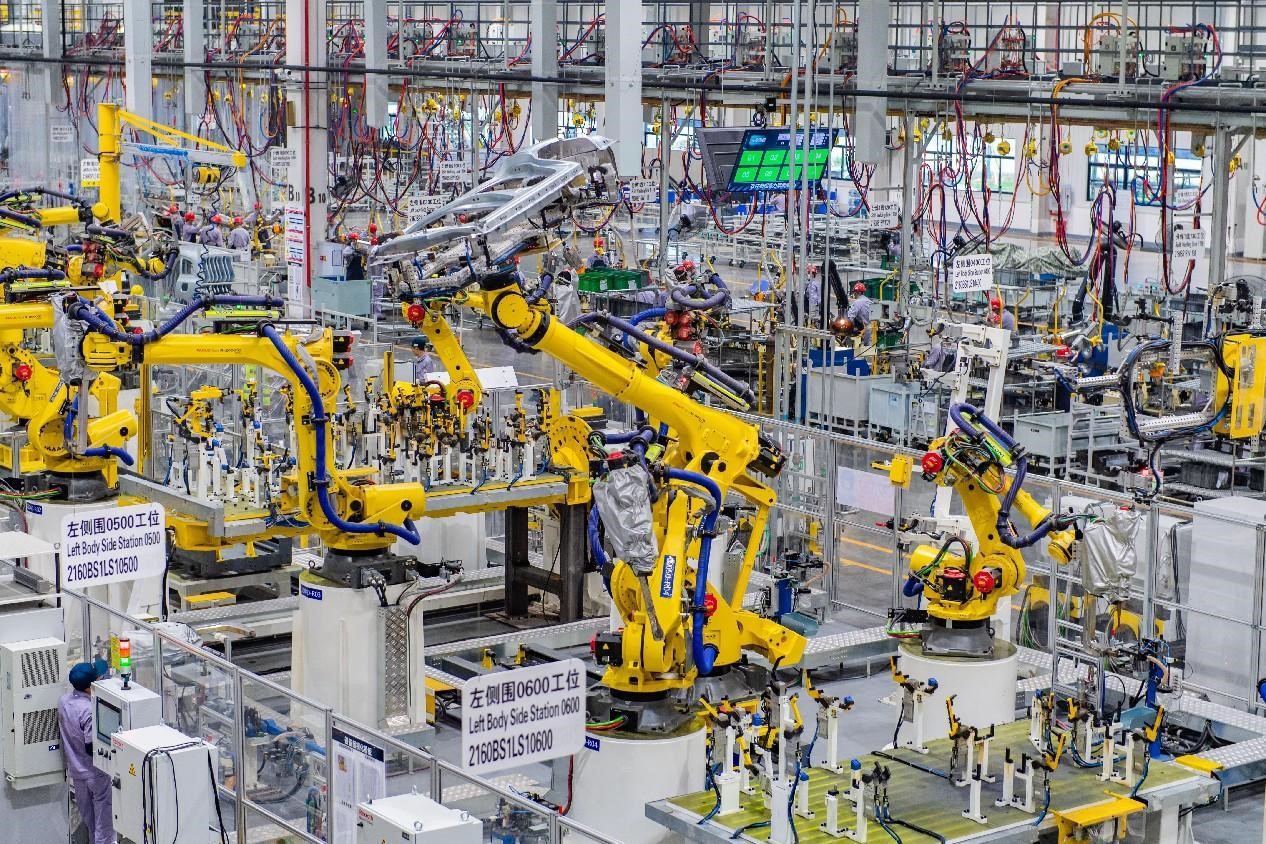

Robotic arms are working in a welding workshop of Chinese electric vehicle manufacturer SERES in Southwest China's Chongqing. (Photo: Sun Kaifang/People's Daily Online)

How can green transition measures be implemented while production remains uninterrupted? Chongqing's answer is to lower energy consumption and improve efficiency.

"Clinker calcination is a key part of cement production," said Han Wei, assistant manager of a cement producer in Bishan district of Chongqing. Coal is the major fuel for calcination. If traditional equipment, techniques and materials are employed during the process, clinker calcination consumes high amounts of energy and leads to pollution, Han said.

In recent years, Han's company has managed to replace part of the limestone needed in the production with calcium carbonate and calcium oxide, which reduces the emission of carbon dioxide generated in the secondary combustion of limestone. This procedure alone lowers the company's cost by over 8 million yuan ($1.16 million) each year.

Relying on big data and intelligent technologies, green enterprises in Chongqing have gradually realized targeted management of energy.

Many enterprises in Chongqing have started greening themselves and building green factories to further improve their performance and profit. Circular production of enterprises, circular combinations of industries and circular upgrading industrial parks are advancing vigorously in the city.